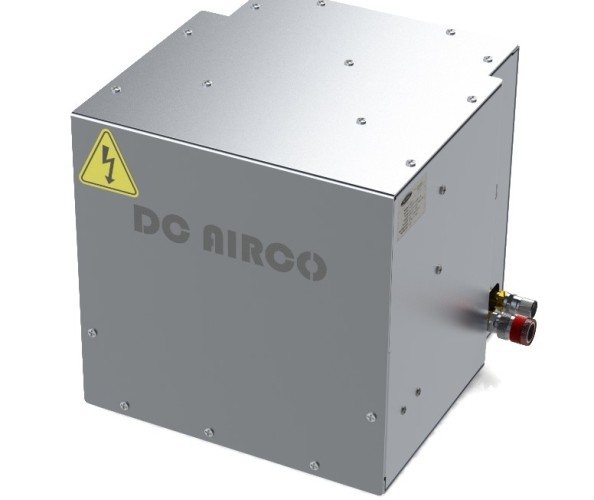

DC5020 - Battery Cooler/Heat-Pump liquid to Air 360Vdc 540Vdc

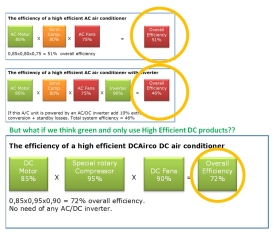

High-efficiency DC powered heat-pump for cooling + heating batteries of electric vehicles such as locomotives, trains, buses, people movers, trucks, POD, defence, Hybrid vehicles (HEV) (PHEV), Electric vehicles (EV) and Fuel cell vehicles (FCV)

Our rugged high performance and low consumption heat pumps are available in

360Vdc (200-420Vdc) or 540Vdc (400-800Vdc) and designed to cool and heat

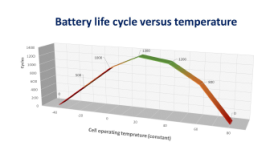

batteries of battery-powered vehicles under heavy-duty conditions. Maintaining

the battery temperature is mandatory to maximize its life spend and characteristics.

The CANopen connectivity delivers performance in terms of scalability user interface as well as straightforward programming, maintenance and servicing. Ideal for fast and easy customization for vehicles such as Hybrid vehicles (HEV) (PHEV), Electric vehicles (EV) and Fuel cell vehicles (FCV)

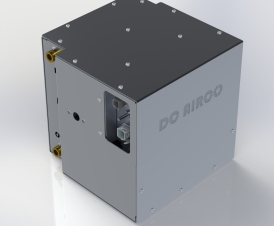

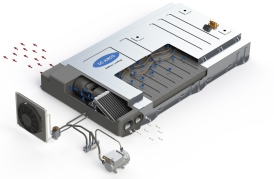

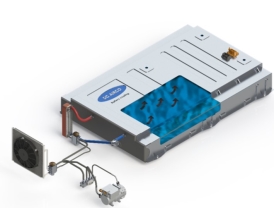

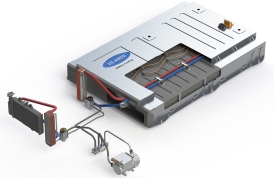

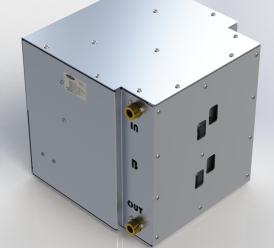

The self-contained box consists of a 2-way condenser and evaporator, high efficient slow starting compressor, and an inbuilt electronic control box. The water pump or outdoor heat exchanger is not part of the standard supply.

Refrigeration |

|

Parameter | Value |

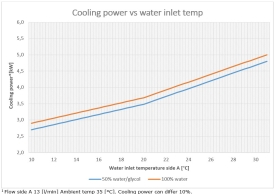

Cooling power (EN-14511-2:2013) | 4 kW 100% water |

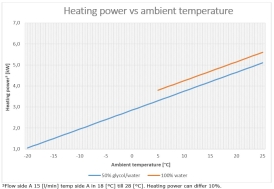

Heating power (EN-14511-2:2013) | 4 kW 50% glycol/water |

Liquid flow | Side A 15 l/min |

Compressor – motor RPM | 1000 – 6000 rpm |

Pressure drop | 35 kPa @ 30 l/min |

Refrigerant | R134a (1,1,1,2-tetrafluoroethane). 1234yf on request |

Refrigerant amount | 700 g |

Refrigerant GWP-AR4 | 1430 |

Refrigerant ODP | 0 |

Safety Classification of Refrigerant (ASHRAE 34) | A1 |

Maximum temperature inlet | Side A: 55 °C ambient (possibly for derating ask salesperson for more information) |

Minimum temperature inlet | Side A: -20 °C |

Maximum ambient temperature | 50 °C |

Minimum ambient temperature | -20 °C |

Storage temperature | -30 °C till 55 °C |

Altitude | 1200m above derating will be on the capacity. |

EER | 7,5 (see graph: Energy efficiency ratio (Cooling)) |

COP | 2,7 (see graph: Coefficient of Performance (Heating)) |

Sealing pressure | 30 barg |

Max glycol mix | Ethylene glycol/water 60% |

Min glycol mix | Ethylene glycol/water 50% (if less than 50% ask salesperson for more information) |

Cooling duty varies on climatic conditions and altitude- consult factory for specific applications. Please note the outdoor heat exchanger needs to be oversized!

Mechanical |

|

Parameter | Value |

Hazard level (according to EN 45545) | HL1 on request |

Liquid connections | G3/4 male |

Weight body | 21 kg |

Weight outdoor heat exchanger | 9,5 kg |

Maximum dimensions without a condenser | 350 x 350 x 350 mm |

Condenser dimensions | 710 x 457 x 115 mm |

Colour | Aluminium |

Colour Control box | Aluminium |

Connect to side A | The device that needs thermal managed |

Connect to side B | Condenser |

Sound power level | 70 dB (A) on 1 m @ 25 °C |

Walkability | N.A. |

Mounting | See 5020-19999-001-B for more information |

Operating angles | 10° see 5020-19999-001-B for more information |

Max water pressure | 4 barg |

Standard refrigerant hose length | 3 m |

Electrical |

|

Parameter | Value |

Software | DC 50xx V1.4 |

Operating voltage of 360 VDC | 240- 420 VDC |

Operating voltage of 540 VDC | 400-750 VDC max 790±5 VDC |

Control voltage | 24 VDC (20-32 VDC) |

Power consumption HV | 0-3,7 kW |

Power consumption LV | 300 W |

Power consumption control max | 42 W |

Degree of protection (components to be protected from water and dust) | IP66 |

Mounting location Control box | In DC 5020 |

Communication | CANopen (SDO only), remote on/off with error signal or self-controlled |

Connector LV | Harting 1A (see 5020-19999-001-B for more info) |

Connector HV | TE HVA 280 (see 5020-19999-001-B for more info) |

Connector Condenser fan | Delphi 12185126 (see 5020-19999-001-B for more info) |

Insulation value HV 360 VDC version | ≥20 MΩ 500 VDC/60S |

Dielectric strength HV 360 VDC version | ≤ 15 mA 2000 VAC / 50 Hz / 60 s |

Insulation value HV 540 VDC version | ≥20 MΩ 1000 VDC/60S |

Dielectric strength HV 540 VDC version | ≤ 15 mA 2500 VAC / 50 Hz / 60 s |

Normative references | ||

Name | Issue | Description |

EN 60529 |

| Degrees of protection provided by enclosures (IP Code) |

MAC directive (2006/40/EC) |

| relating to emissions from air-conditioning systems in motor vehicles and amending Council Directive 70/156/EEC |

DIRECTIVE 2014/68/EU |

| On the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment |

REGULATION (EU) No 517/2014 |

| of 16 April 2014 on fluorinated greenhouse gases and repealing Regulation (EC) No 842/2006 |

EN 378 |

| Refrigerating systems and heat pumps – Safety and environmental requirements |

EN-14511-2:2013 |

| specifies the test conditions for the rating of air conditioners, liquid chilling packages and heat pumps, using either, air, water or brine as heat transfer media |

DIRECTIVE 2014/35/EC |

| on the harmonisation of the laws of the Member States relating to the making available on the the market of electrical equipment designed for use within certain voltage limits |

DIRECTIVE 2014/30/EC |

| Directive on the approximation of the laws of the Member States relating to electromagnetic compatibility. |

Downloads -

- DC5020 - Battery Cooler/Heat-Pump liquid to Air 360Vdc (200-420Vdc) or 540Vdc (400-800Vdc)

- DC 5020 technical drawing 5020-19999-001-B